Filtration

MN self-cleaning rotary filter

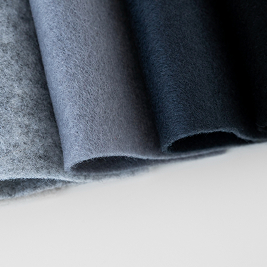

The MN self-cleaning rotary filter is a device designed to filter large quantities of dusty air containing textile fibers and/or other waste materials. It consists of a metal structure and a perforated sheet metal cylinder that rotates on itself thanks to a transmission mechanism. The dusty air passes through the cylinder (from the outside to the inside) and exits the filter head clean and dust-free, ready to be expelled, recirculated into the room, or sent to an air conditioning system. A filter element is installed on the surface of the cylinder, which can vary depending on the field of application, the material being treated, and the amount of air (it can be made of polyurethane, felt, or fur). The filter element is sucked in by a system of nozzles installed on the metal structure which, thanks to a second transmission system, move horizontally along the cylinder. The combined action of rotation and translation ensures complete cleaning of the filter medium, and the collected material is conveyed into a dust collection system.

In sectors other than textiles, the rotary filter can be an excellent alternative to cartridge filters, ensuring significant cost savings and greater longevity.

Inspection and control of the machine can be conveniently carried out at the front of the machine (at the clean air outlet) while the system is running.

The system is modular and based on 4 different diameters. For each diameter, the filter can be made up of one to four modules, in order to best meet the needs of the system and the characteristics of the environment in which it is installed.