Filtration

Pocket filter

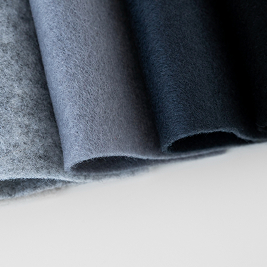

The automatic pocket filter is a machine designed to filter dusty air containing fibers or other waste materials. The air is conveyed into the machine and filtered by a system of pockets made of needle-punched felt, cleaned by a compressed air system that intermittently blows against the flow of air being sucked in. The equipment is equipped with a sequential control panel that allows the working times of the blowing system to be adjusted according to the quantity of air and the material being treated. A hopper with a discharge screw is installed in the lower part of the filter, into which the collected material is conveyed to be pressed and expelled. The action of the screw ensures continuous use of the filter and a reduction in the volume of waste material by up to about one third.

The tubular structure and sheet metal panel infill ensure ease of transport and quick assembly and allow for quick and constant inspections while the system is in operation.

The pocket filter is available in 6 different sizes to cover a wide range of air flow rates and is suitable for the extraction and filtration of dust and materials of any kind, with the exception of explosive or detonating materials.